欢迎进入德国力特LIT阀门官方网站!

咨询热线:13717986720

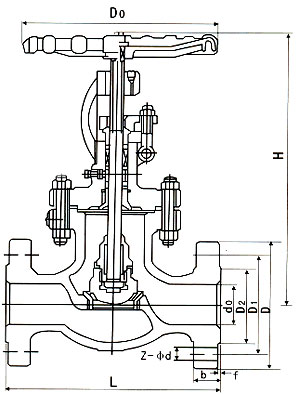

进口法兰截止阀

类别:进口截止阀

品牌:德国力特LIT阀门

德国力特LIT阀门进口法兰截止阀概述:

德国力特LIT阀门进口法兰截止阀是德国力特根据ANSI和API标准生产,阀瓣和阀座的密封面采用不同硬度的司太立(Stellite)钴基硬质合金堆焊而成,密封可靠、硬度高、耐磨、耐高温、耐腐蚀、抗擦伤性能好、寿命长。

德国力特LIT阀门进口法兰截止阀参数:

公称通径:DN15-DN1000

公称压力:150LB-2500LB

设计温度:-29℃-550℃

连接方式:法兰

适用介质:气、水、油、蒸汽、燃气、腐蚀性流体

德国力特LIT阀门进口法兰截止阀部件:

零件名称 | 材质 | ||

阀体/阀盖 | WCB | CF8 | CF3 |

阀瓣 | WCB | CF8 | CF3 |

阀杆 | 13Cr | 304SS | 316SS |

填料 | 柔性石墨 | PTFE编织 | PTFE编织 |

垫片 | 304L+石墨 | 304L+PTFE | 316L+PTFE |

压盖 | WCB | CF8 | CF3 |

填料压环 | WCB | CF8 | CF8 |

德国力特LIT阀门进口法兰截止阀尺寸:

DN | 150Lb | |||||||

in | L | D | D1 | D2 | b | n-φd | H | D0 |

1/2 | 108 | 89 | 60.5 | 35 | 11.2 | 4-16 | 241 | 100 |

3/4 | 117 | 98 | 69.9 | 43 | 12.7 | 4-16 | 241 | 100 |

1 | 127 | 108 | 79.2 | 51 | 14.2 | 4-16 | 242 | 125 |

11/4 | 140 | 117 | 89 | 63 | 16 | 4-16 | 280 | 160 |

11/2 | 165 | 127 | 98.6 | 73 | 17.5 | 4-16 | 286 | 160 |

2 | 203 | 152 | 120.7 | 92 | 19 | 4-16 | 368 | 200 |

21/2 | 216 | 178 | 139.7 | 105 | 22.4 | 4-19 | 387 | 200 |

3 | 241 | 190 | 152.4 | 127 | 24 | 4-19 | 411 | 250 |

4 | 292 | 229 | 190.5 | 157 | 24 | 4-19 | 454 | 250 |

5 | 356 | 254 | 216.0 | 186 | 24 | 8-22 | 455 | 350 |

6 | 406 | 279 | 241.3 | 216 | 25.4 | 8-22 | 541 | 350 |

8 | 495 | 343 | 298.5 | 270 | 28.4 | 8-22 | 651 | 450 |

10 | 622 | 406 | 362.0 | 324 | 30.2 | 12-25.4 | 800 | 450 |

12 | 698 | 483 | 431.8 | 381 | 32 | 12-25.4 | 1231 | 600 |

14 | 787 | 533 | 476.3 | 413 | 35 | 12-29 | 1450 | 600 |

16 | 914 | 597 | 539.8 | 470 | 36.6 | 26-29 | 1645 | 600 |

DN | 300Lb | |||||||

1/2 | 152 | 95 | 66.5 | 35 | 14.2 | 4-16 | 241 | 140 |

3/4 | 178 | 117 | 82.5 | 43 | 16 | 4-19 | 241 | 140 |

1 | 203 | 123 | 89 | 51 | 17.5 | 4-19 | 283 | 160 |

11/4 | 216 | 133 | 98.5 | 63 | 19 | 4-19 | 320 | 200 |

11/2 | 229 | 155 | 114.3 | 73 | 20.6 | 4-22.5 | 322 | 200 |

2 | 267 | 165 | 127 | 92 | 22.4 | 8-22.5 | 399 | 200 |

21/2 | 292 | 190 | 149.4 | 105 | 25.4 | 8-22.5 | 438 | 250 |

3 | 318 | 210 | 168.1 | 127 | 28.4 | 8-22.5 | 464 | 280 |

4 | 356 | 254 | 200.2 | 157 | 31.8 | 8-22.5 | 565 | 350 |

5 | 400 | 279 | 235 | 186 | 35 | 8-22.5 | 614 | 350 |

6 | 444 | 318 | 269.7 | 216 | 36.6 | 12-25.4 | 717 | 400 |

8 | 559 | 381 | 330.2 | 270 | 41.2 | 12-25.4 | 930 | 500 |

10 | 622 | 444 | 387.4 | 324 | 47.8 | 16-28.5 | 1012 | 550 |

12 | 711 | 521 | 450.8 | 381 | 50.8 | 16-32 | 1231 | 600 |

14 | 762 | 584 | 514.4 | 413 | 54 | 20-32 | 1450 | 600 |

16 | 864 | 648 | 571.5 | 470 | 57.2 | 20-35 | 1645 | 600 |

DN | 600Lb | |||||||

in | L | D | D1 | D2 | b | n-φd | H | D0 |

1/2 | 165 | 95 | 66.5 | 35 | 14.5 | 4-16 | 285 | 100 |

3/4 | 190 | 117 | 82.5 | 43 | 16 | 4-19 | 285 | 125 |

1 | 216 | 124 | 89 | 51 | 17.5 | 4-19 | 313 | 160 |

11/4 | 229 | 133 | 98.5 | 63 | 21 | 4-19 | 328 | 160 |

11/2 | 241 | 156 | 114.3 | 73 | 22.5 | 4-22.5 | 365 | 180 |

2 | 292 | 165 | 127 | 92 | 33 | 8-19 | 444 | 200 |

21/2 | 330 | 190 | 149.4 | 105 | 36 | 8-22.5 | 483 | 250 |

3 | 356 | 210 | 168.1 | 127 | 39 | 8-22.5 | 533 | 250 |

4 | 432 | 273 | 216 | 157 | 45 | 8-25.4 | 622 | 350 |

5 | 508 | 330 | 266.7 | 186 | 52 | 8-28.5 | 750 | 350 |

6 | 559 | 356 | 292.1 | 216 | 55 | 12-28.5 | 800 | 450 |

8 | 660 | 419 | 349.3 | 270 | 63 | 12-32 | 927 | 500 |

10 | 787 | 508 | 431.8 | 324 | 71 | 16-35 | 1257 | 600 |

12 | 838 | 559 | 489 | 381 | 74 | 20-35 | 1468 | 680 |